Exhibitor Profile

参展商概况

| |

| Company Name 公司名称 | Inner Mongolia Zhongyu Magnesium Alloy Wheel Forging Co., Ltd. 内蒙古中钰镁合金锻造轮毂有限公司 |

|---|---|

| Country/Region 国家/地区 | Inner Mongolia, China 内蒙古乌海市 |

| Booth Number 展位号 |

Hall.2-2212 |

Company/Product description

公司/产品介绍:

Inner Mongolia Zhongyu Magnesium Alloy Wheel Forging Co., Ltd was established in September 2014. It integrates production, processing and sales of magnesium alloy wheel. Through the introduction of domestic patents, the company has realized the construction project of large-scale production of "magnesium alloy wheels and lightweight component for vehicles". The project has respectively been adopted in the regional and Wuhai's "Thirteenth Five-Year Plan" the major project library. It will be of great significance to the development of automobile industry and the application of magnesium alloy wheel in western China.

Company registered a capital of 60 million yuan and covered an area of 850 mu. The production project achieves an annual production capability of 6 million Mg-alloy wheels and 25 thousand tons of Mg-alloy sheets and profiles.The investment for the first phase of the project is 1.646 billion yuan, manufactuering 1.2 million magnesium alloy wheels and 50,000 tons of magnesium alloy sheets and profiles.

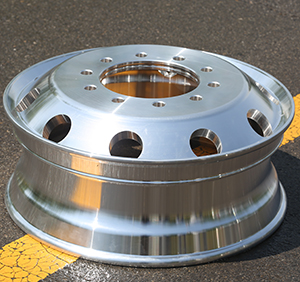

The company produces Mg-alloy forged bub as the main products, with independent intellectual property rights as the technical support of the invention patent. As a product of "Green Engineering Materials for the 21st Century," Mg-alloy wheel hubs have a light specific gravity, which are about 50.7 less weight than the cast aluminum hub and about one third of the weight compared to the forged aluminum hub.Being lightweight is an important measure to save energy and protect environment from fuel vehicles; and is one of the most effective measures to reduce fuel consumption and reduce emissions. It is also one of the most effective measures to reduce fuel consumption and emissions. The use of magnesium alloy wheels can effectively reduce the weight of the whole vehicle. The experimental center of the Great Wall Automobile Co., Ltd. has carried out the test of "taxiing, constant fuel consumption" for the magnesium alloy wheel hub produced by this technology. The test results show that "The fuel consumption of the vehicle equipped with magnesium alloy wheel is about 14% lower than the vehicle with alluminum alloy wheel when it is running in a constant speed at 60Km/H.".

Magnesium alloy is at present used in more than 60 parts in a car, including steering wheel frame, instrument panel, engine valve cover, gearbox shell, automobile body and so on. The use of magnesium alloy to replace aluminum alloy in automobile industry reduces the weight and cost, which undoubtedly opens up the application space of magnesium alloy. Smartphones, superphones and tablets represent the developmental direction of 3C products.Based on the prediction of the popularity of them and the natural adaptability of magnesium alloy shells to the development of such products, (thin aesthetic, good heat dissipation, etc.) there will be a substitute of Mg-alloy for other materials.

Data from the large database of the Institute of Commerce and Industry of China shows that the production of magnesium alloys in China reached 29.78 million tons in 2013 which comparing with 2012 gets a high growth rate as 43.52%, and the domestic consumption of magnesium alloys is 19.59 million tons. In 2014, the production of magnesium alloys in China was 35.83 million tons. In 2015, the production of magnesium alloys in China was 41.5 million tons and the consumption was 30 million tons.

In response to the National Thirteenth Five-Year Plan, lightweight material have become an important development direction of manufacturing material.With the introduction of Mg-alloy forged hub and Mg-alloy profile project of Zhongyu Magnesium Industry Group, it opens the prelude to Wuhai light alloy industry and expands the influence of Wuhai light alloy industry.The company holds the hopes to set up a “China-Wuhai magnesium Industry Base "to attract enterprises in the Northwest region, including Inner Mongolia, Ningxia, Shaanxi, Qinghai, Xinjiang and other provinces in the light alloy industry chain to create an intelligent business card in the lightweight field, extend the industrial chain in the Northwest region, join into the international economic tide, and finally effectively promote the rapid development of the national magnesium industry.

Wuhai trains professional and technical personnel by the "Research and Development training Base for Mg- Alloy equipment Manufacturing", while conveying tthmen to the surrounding areas and to the automobile equipment manufacturing and other related industries throughout the country, it improves the teaching ability of technical talents in the research and development direction of Mg-alloy equipment manufacturing in Wuhai, enhances the teaching influence of Wuhai area, and will lead to a show of brand new business card to the surrounding areas and the whole country.By then, the company will have a management team unitied, pragmatic and efficient, the high-tech transformed from most advanced patent, the allocation of resources reasonable and market prospects broad .With the support of Wuhai and regional government, we will take the spirit of developing the equipment manufacturing industry in the 13th Five-Year Plan as an opportunity to comply with the regional economic development, promote the research and development of magnesium alloy products and extend the industry in an all-round way. Facing the development and construction of enterprises, the company will sprare no efforts with all walks of life to bring out the best!

内蒙古中钰镁合金锻造轮毂有限公司成于2014年9月成立。公司集镁合金轮毂生产、加工、销售为一体。公司通过引进国内专利,实现“镁合金轮毂及车辆轻量化型材”规模化生产建设项目,项目已分别落入自治区、乌海市“十三•五”规划重大项目库,建成后将对中国西部汽车产业发展和镁合金轮毂应用领域具有极强的示范意义。

公司注册资本6000万元,占地面积为850亩。镁合金锻造轮毂生产项目实现年产600万只镁合金轮毂和25万吨镁合金板型材的生产规模。项目一期投资为16.46亿元,实现年产120万只镁合金轮毂和5万吨镁合金板型材的生产规模。

公司以生产镁合金锻造轮毂为主要产品,利用具有自主知识产权的发明专利为技术支持。作为“21世纪的绿色工程材料”的产品,镁合金轮毂具有比重轻,与铸造铝轮毂比较可减轻约50.7%,与锻造铝轮毂比较可减轻约1/3的重量,轻量化是解决燃油汽车节能环保的重要举措,也是汽车降低燃油消耗及减少排放的最有效措施之一,使用镁合金轮毂可有效减轻整车重量,长城汽车股份有限公司实验中心为利用该技术生产的镁合金汽车轮毂进行了“滑行,等速油耗”方面的测试,测试结论为“更换镁合金轮毂汽车在等速60Km/H行驶时,油耗要比铝合金轮毂节省14%左右”。

目前汽车上共有60多个零部件使用镁合金,其中方向盘骨架、仪表盘、发动机阀盖、变速箱壳、汽车车身等部位应用最多。汽车产业使用镁合金替代铝合金部件在减轻重量的同时也获得了成本的降低,这无疑进一步打开了镁合金应用的空间。智能手机、超极本及平板电脑代表了3C产品的发展方向,基于对智能手机、超级本、平板电脑的普及速度预测,以及镁合金外壳对此类产品发展要求的天然顺应能力(轻薄化、美观化及散热性等)导致的对其他材料的替代。

中商产业研究院大数据库数据显示:2013年我国镁合金产量为29.78万吨,同比2012年,增长率高达43.52%,国内镁合金消费量为19.59万吨。2014年我国镁合金产量35.83万吨。2015年我国镁合金产量为41.5万吨,消费量为30.0万吨。

为响应国家十三五发展规划,轻量化材料成为制造业材料的重要发展方向。随着中钰镁业集团的镁合金锻造轮毂和镁合金型材项目的引进,开启了乌海市轻合金产业的序幕,为扩大乌海地区轻合金产业影响力,在乌海市成立“中国-乌海镁产业基地”,吸引西北地区,包括内蒙、宁夏、陕西、青海、新疆等省份轻合金产业链相关企业,在西北地区打造轻量化领域智能名片,延伸产业链,融入国际经济大潮,有效推动国家镁产业的高速发展。 乌海市以中钰镁业集团镁合金高新技术产业项目建设为奠基,借助中钰镁业集团的两所研究院“产、学、研”创新平台,进行国家镁合金科技攻关课题研究,以新技术、新材料,服务于新能源汽车、轨道车辆、航空(民用航空)、航天、日用电气、民众生活等各类行业,实现产业转型升级,彻底改变资源型城市的发展思路,打造以金属镁冶炼、镁合金压铸件、镁合金板材及汽车轻量化装备应用产品为主导的1000亿元镁产业基地,着力推动组建大型镁产业集团,力争在15年内,使我市这一优势特色产业超过1000亿元规模。

乌海通过“镁合金装备制造研发实训基地” 培养的专业技术人才,向周边地区及至全国汽车装备制造相关行业输送,同时提高乌海市镁合金装备制造研发方向技术人才的教学能力,也提升了乌海地区的教学影响力,向周边地区以及全国亮一张崭新的名片。

届时,公司会拥有一批团结、务实、高效、进取的管理团队,最先进专利转化的高新技术,合理的资源配置,广阔的市场前景。在乌海市、自治区两级政府的大力支持。我们将以“十三·五”期间大力发展装备制造业为契机,顺应地区经济发展,全面推进镁合金产品的研发和产业延伸。面对企业的发展建设,公司将与社会各界奋力拼搏,勇创佳绩。

Reliable International Exhibition Services Co., Ltd. &

Topic International Exhibition Services Co., Ltd. All rights reserved.

京公网安备 11010502042914号,京ICP备19031008号-3